After I finished my time at Paragon Machine Works, I decided that I wanted to try my hand at building bike frames. I had a great mentor there who had several years’ experience as a framebuilder, and I had a road bike that I really didn’t like, so I thought that I should learn to build bike frames by building myself a new road bike frame.

I took the advice of a friend who had built a frame himself and decided to build my first frame with lugs. A lugged construction is a little easier and more forgiving for alignment and fixturing when brazing without a jig, so it makes sense why he recommended this. Though I was initially headstrong and wanted to fillet braze my first frame, I slowly but surely realized that building bike frames is a skill which is developed over years of trial and error, and it would be foolish to assume that I could master the art of fillet brazing on my first ever frame.

As it was, I decided to use lugs. I wanted to make my frame a geometric copy of the 2019 Specialized Tarmac in a 56, a bike which I had heard was delightful to ride. However, I wanted to be a little more creative so instead of an ordinary road bike frame, I decided to add a second top tube.

It’s funny. I constantly get asked the question “what’s the second top tube for?” as if everything on a bike is required to have an explicit and stated purpose. Don’t we ride bikes to enjoy them? My initial response to this question is “what is art for?” I think it’s a fair question. Why is it that my decisions in this creative expression have to have a purely functional reason? Sure, most of the decisions are the result of pragmatism and carefully weighed tradeoffs, but if I were solely building this machine for the purpose of functionality, I would’ve bought a bike off the shelf. More often however I will say “Why do your wheels have a different number of spokes than mine?” or something like that to show how irrelevant and not entirely purpose-driven some decisions are.

I made a 2D solidworks drawing of the bike I wanted to build so that I could translate from the angle measurements that are pertinent to expressing the geometry to the rider/designer to the angle measurements that are pertinent to the fabricator, ie the angles at which to miter the tubing. From that I was able to survey the available lugs and purchase a combination which had the tubing angles and tubing widths to suit my desires.

I went with Longshen head and seat tube lugs, a Kirk Pacenti bottom bracket lug, and some unnamed rear dropouts from Bicycle Fabrication Supply. Interestingly, the Specialized Tarmac is made with a proprietary fork whose geometry no other manufacturer has since replicated in terms of length and offset. Because of this, I decided to use an ENVE fork because it was the closest I could find in terms of measurements.

After the tubing and lugs showed up, I made very minimal progress on the bike for a few months because I was much more focused on doing well in school than I was on pursuing this craft. Once summer came around, I moved back from Salt Lake City where my tools were to Mill Valley, where my parents were. This meant that I couldn’t make any progress the whole summer either. Or so I thought, until Pete Olivetti, the builder at Olivetti Bicycle Company and a former coworker, called me out of the blue and asked if I wanted to help him with a production run of bikes he was making for the bike shop we both used to work at. I gladly agreed to come out to Boulder to help.

I flew out in late July and stayed at his house in Two Mile Canyon near Boulder Colorado for a few weeks to assist in everything except for welding a batch of 8 frames. The bikes we were making were a full size run of custom gravel bikes for Tam Bikes in Mill Valley, California. Calling on my manual machining experience from working at Paragon Machine Works, I mitered all of the main tubes and all of the chain stays for all 8 of the bikes. I also constructed a very rigid and very repeatable setup for drilling the appropriate holes required for Paragon Machine Works Flat Mount disc brake caliper barrels. Additionally, I made an equally rigid fixture for drilling water bottle boss holes, which there were 7 of on each bike. All in all, I drastically sped up the production of these bikes and allowed Pete to focus entirely on making clean, consistent welds.

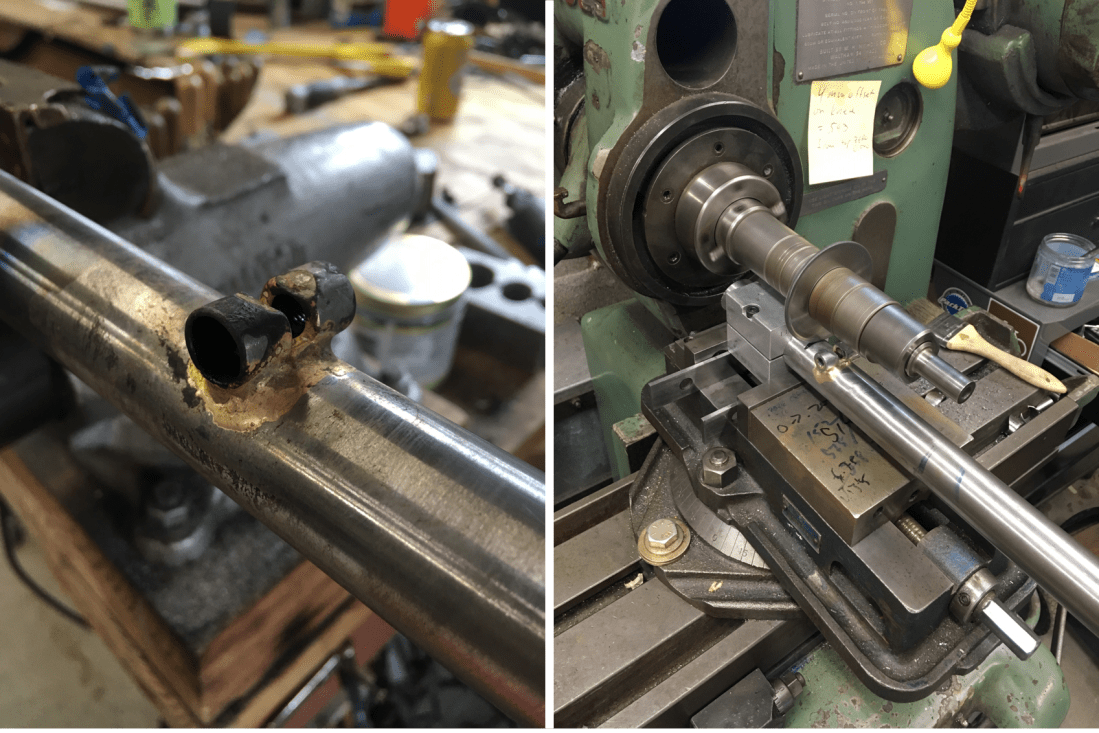

In the after hours and on the weekends, I made my own bike. I mitered all of the tubing using his dedicated setups (two Nichols horizontal mills with Sputnik Tools mitering fixtures) and I carved my lugs using his lug vice. Both of the seat tube lugs were significantly modified from their stock appearance to the way they look now, as shown in photos above. I then used his frame jig to braze my frame together and ensure that it was planar and straight.

I wasn’t extremely pleased with the seat post binder that was native to the seat tube lug so I decided to file it off, as shown in the photos above. This meant that I had to come up with a way of clamping the seatpost, either by brazing on a traditional binder, or otherwise. I took advice from Pete and inspiration from Nate Zukas, a builder in Georgia, and relocated the binder further down the seat tube. I am very pleased with the result.

Pete offered excellent fabrication and design guidance and helped me make better decisions about the order in which I put the bike together. I learned a lot from Pete and I learned a lot making this bike and I am extremely thankful for the opportunity I was given to pursue this creative expression.

After many many hours of cleaning up my shorelines and filing my fillets, I sent the frame and fork off to Ollie Cleveland at Dark Matter Finishing for a paint job. I went with a powdercoat finish in RAL 6000 on the frame and the fork. The bike is called “Sue” after a dear friend’s mom of the same name who was recently taken too soon from this earth. A cyclist herself, this bike is a physical reminder of her and her spirit.

Finally, a word about the serial number: TJA 00. Because numbering should start at zero according to my opinion. And indices in C and many other computer programming languages start at 0. And, as enumerated by Edgar Djikstra in his 1982 remark “Why numbering should start at zero,” it is an expression of mathematical beauty. As a mathematically inspired person, I could not pass up on the opportunity to include mathematical beauty in my creation, even if it was so minute.

Once back from paint, I dressed the frame with Campy Super Record 11 and a Steve Potts cockpit that was given to me by my father. I am extremely lucky for this gift and it really completes the bike. It gives me immense satisfaction to be able to ride a bike that I made with my own two hands. I’m sure this one won’t be the last.