Having recently moved to Salt Lake City for school, I found myself in town when NAHBS 2017 came around. NAHBS stands for the North American Handbuilt Bike Show, and it showcases bikes, frames, and components from folks who make their components by hand in the USA. Having grown up in a place where the weather made it possible to ride bikes year-round, I had begun to get pretty restless not being able to ride. I was looking at all sorts of bike related things in any free time I had and I really couldn’t get the idea of riding and warm weather out of my head.

All winter long I’d been lusting after a couple of bikes that were loosely related, but I didn’t like any of them enough on their own to justify purchasing one. I guess you could say that I wanted a combination of three or four different bikes in one. Already knowing that I was in the market for a bike that hadn’t been created yet, I figured that NAHBS was the perfect place to find both inspiration, and a builder who could turn my vision into reality. In addition to that, my dad, who loves hand-built bikes almost more than I do, was in town for that weekend, so I figured it would be fun to go the show regardless. The show was great, and it gave me a lot of ideas. I took some pictures of bikes that I liked, and went home to try and put my vision into a list of objectives I’d like to have met.

After I had thought about what exactly it was that I wanted, it was time to choose a builder. I am originally from Marin County, California, so under previous circumstances, I would have had any of five or more builders in a 25-mile radius to choose from to make my frame, all of whom I could sit down with and have a conversation about exactly what it was that I was looking to create. The ability to have a face-to-face conversation with the builder was a large part in my decision: I really wanted to express exactly what it was I was looking for. This led to a trawling of various cycling news sites that covered NAHBS after the show, and ultimately to my discovery of SaltAir Cycles. I selected SaltAir Cycles because not only were they the given the Best New Builder award, but they are also based out of the Liberty Wells neighborhood in Salt Lake City, just 15 minutes from my new home.

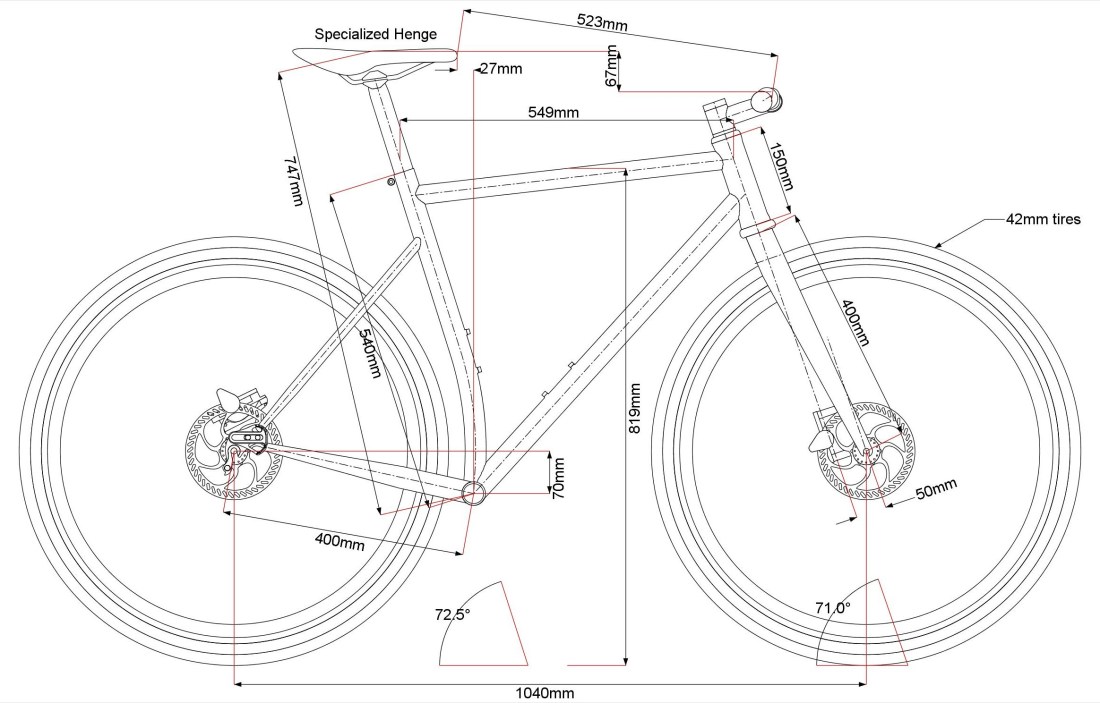

I emailed Matt at SaltAir asking if I could come down and check out his shop and talk about the bike I wanted to build, and he replied almost immediately. We talked over email and then in person for a while, and after our conversations I was pretty sure he could build what I was looking for. I sent him a list of my objectives, which included a 44mm headtube, Paragon Machine Works flanged sliding dropouts with 142x12mm geared inserts for a post mount disc brake, a 68mm BB bb shell, shift cable routing for a rear derailleur only, clearance for a 700x43c tire in both front and rear, a curved seat tube with a radius to match a 700x4Xc rear tire, seat stays that intersected the seat tube below the top tube, a 31.6mm seat post, a 31.8mm diameter top tube, a 42mm diameter down tube, a REN GX-1 fork with the custom Ti rack they made, and braze on’s for a rear rack. I wanted to somewhat closely match the geometry of the OPEN UP, which I had heard so much about. I wanted to make the bike a little less aggressive and “road bike like” than the OPEN, so I opted for a longer head tube, and a much shorter chainstay.

Matt translated this information into a CAD drawing of my future frame that assumed the ride position of my mountain bike, a Santa Cruz Tallboy 3. I OK’d the drawing, and all of a sudden, the construction of my frame was underway. Matt kept me updated and involved throughout the build process, and I made a few visits while he was building it to check out his work and the progress.

Some two months after I initially contacted him about making a frame, it was ready to go out to paint. I took a while to think about what color I wanted and I ultimately arrived at the decision of using RAL 7016 for the frame and fork, and RAL 9001 for the words. What I did not know was that Matt had new graphics up his sleeve that were a massive improvement on his previous graphics. My frame was the first to receive these updated graphics, and I must say that I am extremely pleased with how they came out.

I wasn’t going to spend all the time I did thinking about the design of the geometry of the frame without planning out the most appropriate components with which to adorn my new bike. I wanted to use Hunter Smooth Move handlebars, a Paul Components Boxcar stem, WTB KOM rims, White Industries CLD Hubs, a Thomson seat post, a Specialized Henge saddle, Specialized Sawtooth tires, a King Cage Iris water bottle cage, a Velo Orange Mondo large water bottle cage, Specialized SIP XL grips, and Shimano XT Pedals. I knew that I wanted to initially set it up as a geared bike, and I happened to have a hardly used 11-speed Shimano XTR shifter, derailleur, and cassette from an old bike. That old bike also gave me the SRAM Level Ultimate brakes that I ended up putting on this bike.

Originally, I asked Matt to use a 68mm bottom bracket shell so that I could use the ROTOR cranks that I had on the bike that this was replacing. However, due to the constraints of the extremely tight chainstay/bottom bracket intersection, and the fact that he did not dimple the chainstay to clear a chain ring, I was unable to use the ROTOR crankset. This was a bit of a bummer because the ROTOR cranks were expensive, and I now just have them occupying space on a shelf. However, this did give me a reason to have Matt order me some White Industries G30 cranks, which I had been lusting after. To make it up for the inability to use my cranks, Matt was able to secure a pre-production White Industries Headset as well, which I was very happy about. Not such a bad tradeoff.

My final detail was inspired by the utilitarian nature of this bike. While I knew that I would be riding it as a gravel bike and occasionally as a touring bike, the real purpose was to have something I could use for a commuter. I ride this bike to class and to get groceries nearly every day that I can, weather permitting. As a result, I lock it up against metal racks a lot. Anticipating this and not wanting to scratch the powdercoat I had so carefully thought about, I decided to laser cut a top tube protector from a piece of Horween Chromexcel leather. After stitching this protective measure on with waxed black upholstery thread, the bike was complete.

This bike is a lot of things, and it’s a lot of me and what I like about bikes. I totally nerded out on every aspect of it, as I am apt to do, and as a result it turned out to be exactly what I was looking for. I tried to use as many components as I deemed reasonable that were made by a loose group of people who claim membership of something called “SOPWAMTOS,” which stands for “Society Of People Who Actually Make Their Own Shit.” Not only are their components every bit as good or better than mass produced components, I felt that their mantra was in line with the bike I had created. I absolutely love every facet of how it rides, and I am immensely satisfied that it is entirely my creation. I put my cycling heart and my mechanical soul into the design and creation of this bike and ended up with something that is entirely unique, rides beautifully, and gives me a feeling of pride every time I look at it.

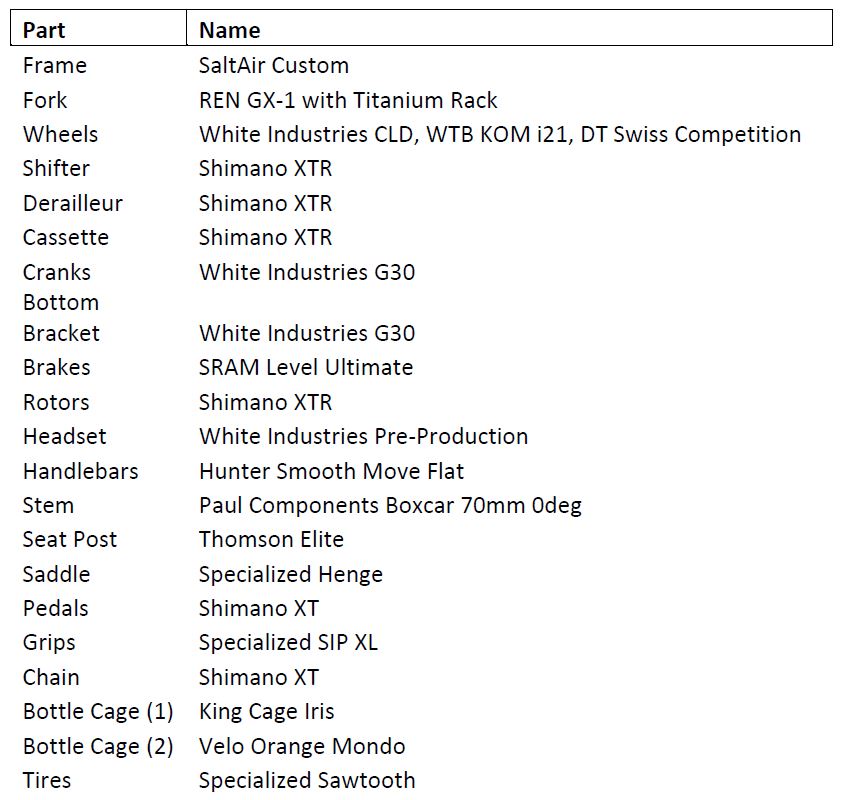

Here is the exact spec: